Micron, Etalon, Proton

Industrial balancing machines and business equipment.

Full cycle design and manufacturing from A to Z.

The most affordable balancing machines on the market with 18 months warranty.

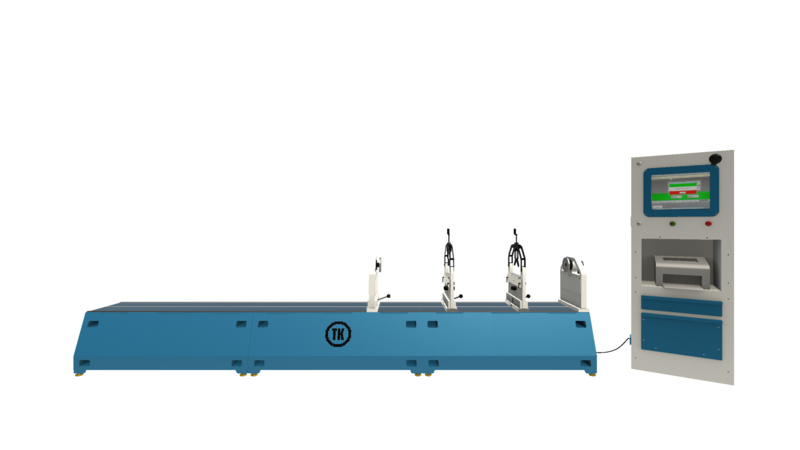

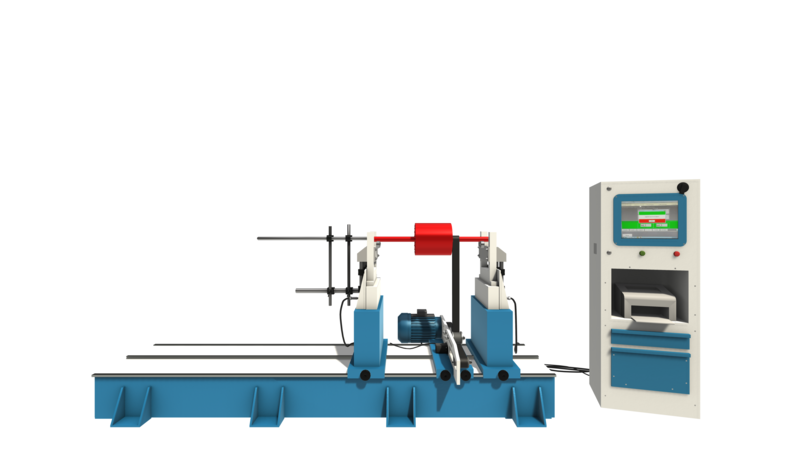

Universal balancing machine Proton 4x-4500.

Industrial series machine is designed for balancing of any cardan shafts and rotors weighing up to 500 kg.

Micron Series

For balancing lightweight rotors

Etalon Series

For balancing medium weight rotors

The first experimental balancing machine of off-resonance type was developed in 2015

A horizontal machine for dynamic balancing of elongated cardan shafts was manufactured under the careful guidance of Prof. Dr. M.G. Yarullin.

Advantages of our machines

A few advantages of our balancing machines and equipment:

Quality components

Warranty 18 months

Industry 4.0 compliant

Working in a unified network

NDP and Training as a gift

Unique support clamps

Wireless sensors

EAC certified

0

Types of machines

0

Manufactured

0

Companies work on our machines

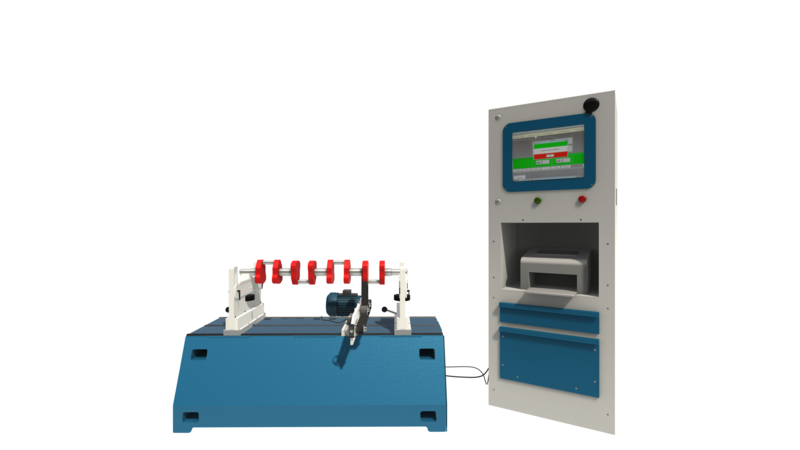

Micron" series machines

Designed for high-precision dynamic balancing of light bodies of rotation from 50 g to 100 kg

Micron series machines are produced with pre-resonant supports and force sensors, as well as with non-resonant supports with vibration sensors. There is a variant of machines with digital, high-precision, three-axis wireless sensors of the new generation Industry 4.0.

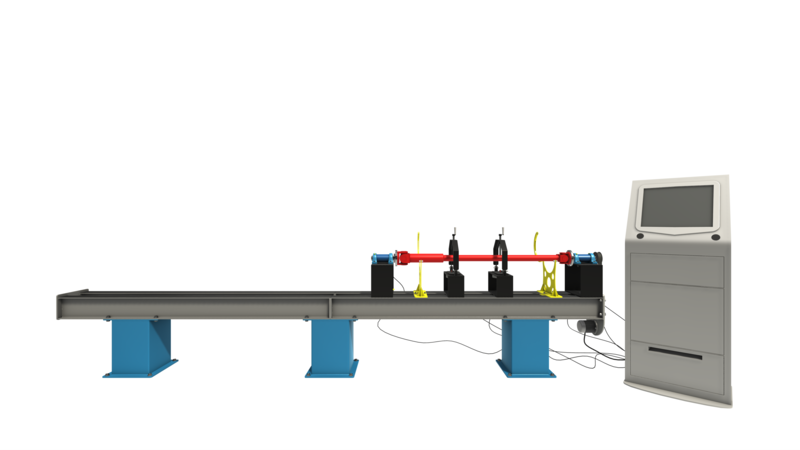

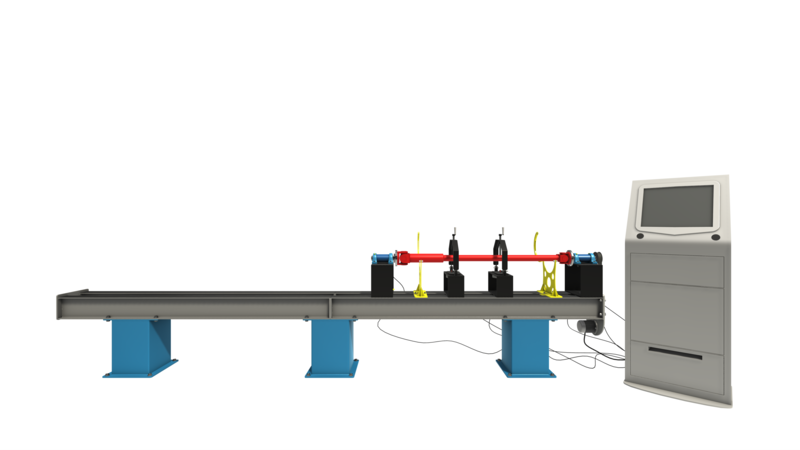

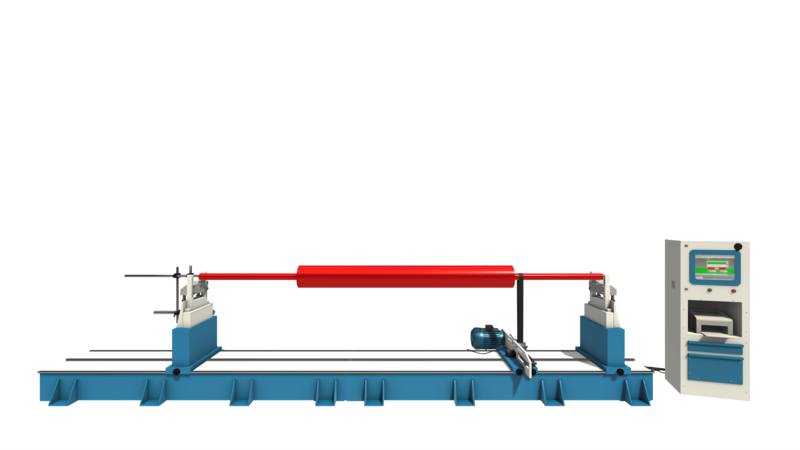

Etalon" series machines

Designed for dynamic balancing of cardan shafts with weight up to 150 kg, length up to 6000 mm.

These machines are the most affordable on the market. Ultra-precise and reliable. Resonant type with vibration sensors, available with digital, wireless three-axis sensors of the new generation Industry 4.0.

Proton-profi" series machines

Specialized machines for dynamic balancing of crankshafts, flywheels, rotors, etc.

This type of machines is designed specifically for individual tasks. Universal version is possible. Machines only in pre-resonance version with built-in force sensors in supports. There is also a version with digital, wireless sensors of the new generation Idustry 4.0.

Proton 2x-3000 series machines

Industrial semi-heavy duty series

These machines are designed for dynamic balancing of any body of rotation up to 3000 kg. This series includes machines up to 1000 kg, up to 2000 kg. Machines of pre-resonant and non-resonant type with built-in force sensors or accelerometers.

Proton 2x-6000 series machines

Industrial series

These machines are designed for dynamic balancing of all bodies of rotation weighing 3000/6000/10000/25000 kg. This series includes machines up to 6000 kg, 10000 kg and 25000 kg. Machines of pre-resonant and non-resonant type with built-in force sensors or magnetic vibration sensors-accelerometers.

Welding bench "SWA-4000"

Unique in its kind

Stand for automatic assembly and welding of any cardan shafts for repair shops and for serial factory cycle Learn more

"Whether you choose to build your own balancing machine or purchase a new one, DBC - ViBEx can provide the best available tools on the market to accomplish your balancing goals."

Rafael Gabdrakhmanov

Book a consultation with the developer

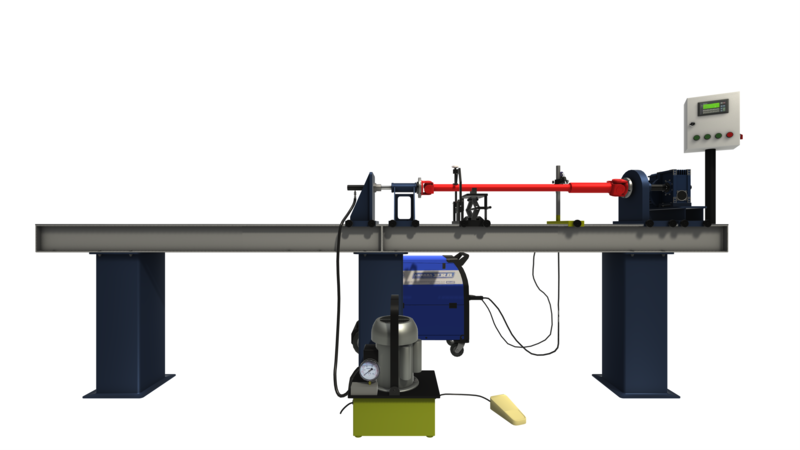

Proton 2x-2000" machine

Specialized balancing machine for two-axis cardan shafts with length not more than 2 meters. The machine is designed for serial production of reinforced cardan shafts of Niva cars.

Industrial design

We are able to anticipate market requirements and offer original and innovative technical solutions. We are committed to the highest quality products. Over the years we have built up a highly professional and experienced technical staff, which today consists of highly qualified engineers and designers. DBC experts follow each new project step by step with sophisticated data processing systems: from characterization analysis to specification, from prototype realization to performance testing. And we are evolving towards Industry 4.0.

Overview of the popular machine

The Proton 4x-4500 is a benchmark among balancing equipment due to its high accuracy, reliability and ease of use. This machine is designed to provide exceptional accuracy when working with driveshafts, which makes it an indispensable tool in automotive and manufacturing shops. Its popularity is not only due to its accuracy, but also due to its ease of maintenance, which significantly reduces the time required to prepare and perform work.

Wireless sensor

Three-axis sensor for real-time vibration diagnostics and dynamic balancing.

Proton 4x" machine

Industrial machine for dynamic balancing of cardan shafts up to 500 kg.

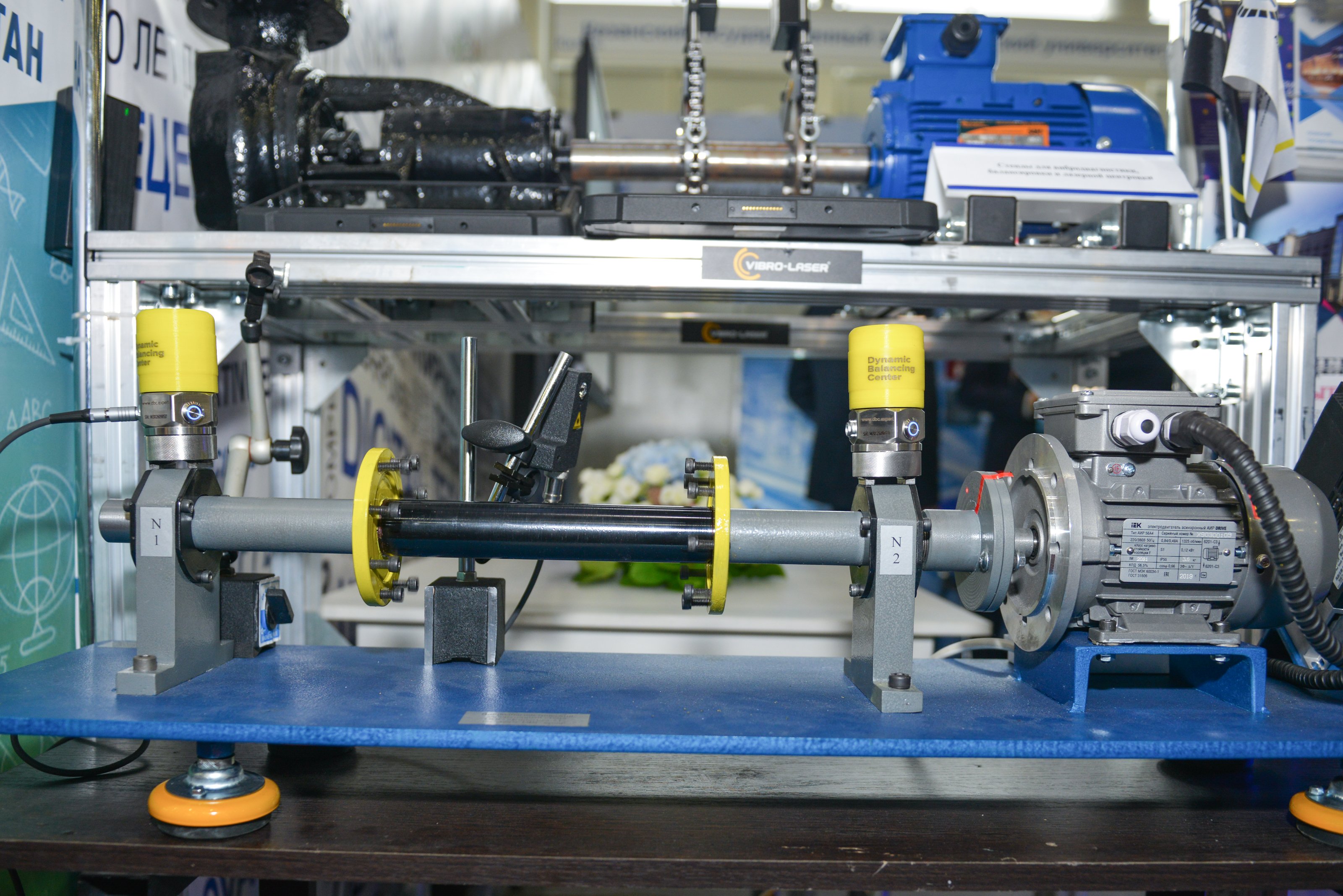

Laboratory bench

Micron series bench for vibration diagnostics and balancing.

Remote Expert Support

Through our global support network, our team of highly skilled technicians provide timely support to our customers who manage through Remote Expert modules 24 hours a day, 7 days a week, 365 days a year.

We work for the whole world

DBC Industrial Division designs, manufactures and exports horizontal and vertical balancing machines suitable for dynamic balancing of any rotor, with manual or automatic unbalance correction. In addition,our developments include fully automatic machines....

Main production and office locted in:

Minareliçavuş Mah. Dökümcüler Sitesi 105. Sk. No:54/1 Nilüfer / Bursa, Tukey

Take part in the online production of your machine

Become a participant in the production of your machine. Step-by-step online production of the machine as you receive funds on your current account and their development. Surprisingly, we have taken this step to ensure that as many people as possible get a balancing machine that will start making a profit immediately. Under this program, the lead time and cost are increased by 10%.

Reference rotor

The reference control rotor is designed specifically for precise adjustment and calibration of equipment on balancing machines, manufactured by the renowned company Mashinostroitelny Zavod VATAN Ltd. The variety of models of these rotors ensures their perfect compatibility with balancing machines of different capacities.

Each test rotor is a perfect combination of shaft and disk. The shaft is supported by angular contact bearings, which are reliably protected against misalignment by special circlips. The connection between shaft and disk is ensured by a threaded recess and is backlash-free due to the tight fit in the smooth part. Precise axial positioning of the shaft in relation to the disk is achieved thanks to the unique seating area on the border between the threaded and smooth parts. The shaft-to-disk connection point is designed to allow easy installation or removal of the angular contact bearing for routine inspections or replacement when worn.

Each manufactured control rotor is manufactured from quality steel, strictly complying with GOST 20076-2007 standards. Additionally, they are tested for quality in a specialized laboratory using non-destructive testing methods. The package includes specially selected control weights, as well as a full package of documentation - this includes a certificate of certification and a detailed methodology for testing balancing machines, which allows to confirm compliance with all the stated characteristics.

Have you found what you need?

Get quick answers to your questions by contacting our development or technical support team. Contact us by email or directly via live chat.

Ask a question about the equipmentFill in the form and a balancing equipment manager will contact you.

We will give you a qualified answer to any of your questions